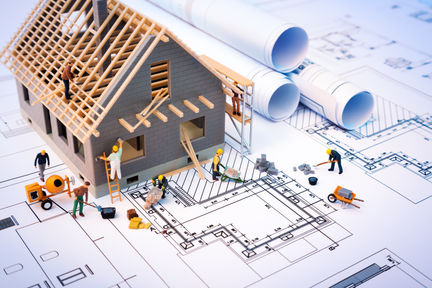

Your Home Journey Starts Here.

Find the regulations, guidelines, construction professionals and tradespeople required for every building stage.

What is your project?

Search building regulations, find local professionals, get the latest grant info, use our free cost calculator and lots more

Already have an account?

Sign In

View Our Inspiration Section

Explore Housebuild

BE INSPIRED

Find inspiration for your next project, shop the look and much more...

Set of Three Wooden Top Lamp Tables with Black Metal Legs - Fiji

Set of Three Wooden Top Lamp Tables with Black Metal Legs

€399.0

INC VAT

Grey Fabric With Walnut Armchair - Henrick

Grey Fabric With Walnut Armchair - Henrick

€999.0

INC VAT

Light Grey Fabric RHF Corner Chaise - Boyne

Light grey Fabric RHF Corner Chaise

€2399.0

INC VAT